Heatless toner transfer

The need:

For my different projects I need to make prototype circuits without investing in equipment that would only be used rarely. In the different possible solutions there are:

- draw the circuit by hand, if possible, with a marker directly on the copper plate. Clearly the quality is not there but for very simple small circuits it is practical.

- transfer by exposure with presensitized plates, presensitized varnish or presensitized film sheets. Clearly this is the best method, it allows to realize very precise and reproducible circuits. I’ve never tested it yet.

- Hot laser printing transfer with an iron, I have never managed to get a correct result, I must not be good at it. Other methods exist with a document laminator which seems to give very good results.

- cold transfer of laser printing by dissolving the printing. This is the method I will describe and which for me gives good results with a minimum of effort even with rather fine traces.

The material:

You will need access to a laser printer. The printing of the typon will be reversed with all the depth parameter from black to full. The paper used may be pages from glossy magazines, I didn’t get good results with photo paper it left too much paper on the plate.

Copper plate.

Household alcohol and acetone to carry out the cold transfer solution and cleaning of the circuit.

An indelible fine mark to correct the tracks after the transfer if necessary.

Bins adapted to the size of the circuit which must be made of plastic or glass.

A product to engrave, I prefer ferric perchloride even if it’s really disgusting.

!!! WARNING!! : it is imperative to have protective gear, waterproof gloves, goggles and protective mask.

The realization:

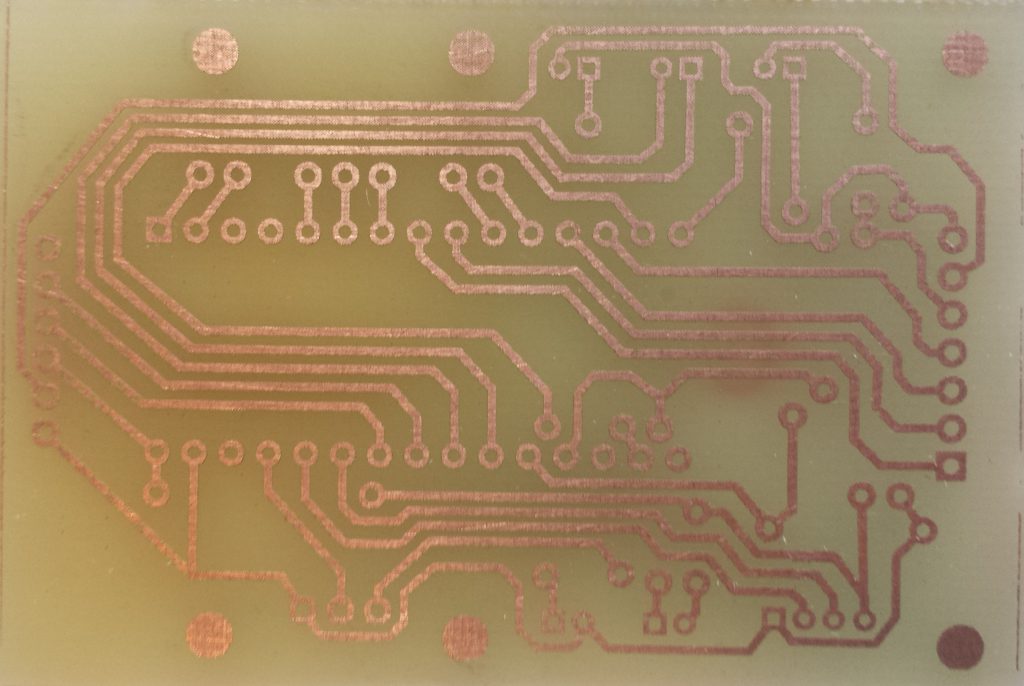

The typon:

It is printed in reverse on glossy paper (magazine or advertising page) using a laser printer.

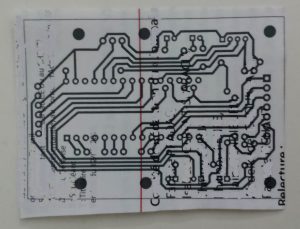

typon

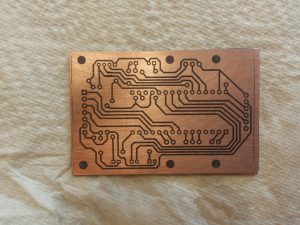

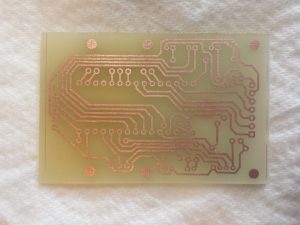

The copper plate:

A piece of copper plate corresponding to the dimensions of the typon must be cut out. Clean it thoroughly with a Jex pad or very fine sandpaper, then rinse it with water and dishwashing liquid. Finally, finish by wiping with an acetone cloth to remove any greasy residue that may remain. This preparation is very important because it will affect the quality of the transfer. CAUTION: after cleaning, do not place your fingers on the copper side.

The magic solution:

I then make a mixture of 60% household alcohol with 40% acetone and deposit a thin layer of this solution on the copper plate. The proportions may vary slightly depending on the products used.

Cold transfer:

Then I quickly place the acetone evaporates, the typon, printing towards the copper side, on a plate by pressing lightly with a stick in order to bring the mixture and the drawing into contact over the entire surface of the typon.

After about ten seconds I press firmly on the typon with a flat surface (pan butt for example) for 1 minute without moving. Then I wait 3 or 4 minutes so that the alcohol and acetone finish evaporating.

I put the plate with the typon glued on it in warm water and wait a good 5 minutes.

The sheet will normally peel off on its own. If this is not the case, remove it very carefully, starting with a corner. I thus obtain the traces on the copper side. It may be necessary to rub slightly with your fingertips to remove the remaining paper or characters from the plate. Do not insist or the trace will disappear.

Engraving:

It is made with ferric perchloride. It is very, very dirty, stained terribly and irremediably, and finally extremely dangerous for the environment, but it is not an acid. It should be poured into a glass or plastic container. Iron perchloride is more reactive when it is warm, so I made a small water bath with hot tap water.

I stir slightly continuously to create a wave on one side and on the other, so the exposed copper will gradually dissolve. I check by transparency that the copper has been removed everywhere, then I rinse the plate with clear water.

The remaining iron perchloride must not be emptied directly into the sink, it must be put in a bottle and taken to a waste disposal centre.

After cleaning the plate with acetone to remove printing marks, it is ready for re-cutting to the correct size and drilling.